Find the best modular elevator for your project.

The first place to start is an overview of the main types of elevator drive systems. Click on any header to view and download drawings for standard models.

Hydraulic Elevators

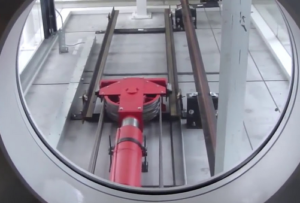

Hydraulic elevators are supported by a piston (or pistons), also called jacks, located at the bottom of the elevator pit. To move the elevator up, an electric motor activates a pump, which pushes hydraulic oil into the jack. The oil causes the piston to push up, raising the car. To move the elevator down, a valve releases the fluid from the jack, allowing it to move back down, lowering the car. Hydraulic elevators are used for low-rise applications of 2-6 stories and travel at a maximum speed of 200 feet per minute. The machine room is typically located adjacent to the hoistway at the ground level.

Holeless Hydraulic

Learn More

Machine Roomless (MRL) Hydraulic

Learn More

In-Ground Hydraulic

Learn More

Roped Hydraulic Elevators

This is a hybrid hydraulic/traction drive system. These elevators have the piston attached to a sheave with a rope passing through it. One end is attached to the car, while the other is secured at the bottom of the hoistway. It acts as a pulley, allowing two feet of car travel for every one foot of jack travel. Roped hydraulic elevators extend the total rise of a hydraulic system to approximately 60 feet without installing a jack below the pit level. Roped hydraulic elevators are custom and can be built to your unique project specifications.

This is a hybrid hydraulic/traction drive system. These elevators have the piston attached to a sheave with a rope passing through it. One end is attached to the car, while the other is secured at the bottom of the hoistway. It acts as a pulley, allowing two feet of car travel for every one foot of jack travel. Roped hydraulic elevators extend the total rise of a hydraulic system to approximately 60 feet without installing a jack below the pit level. Roped hydraulic elevators are custom and can be built to your unique project specifications.

Traction Elevators

Traction elevators are lifted by ropes that pass over a sheave (pulley) attached to an electric motor above the elevator shaft. The other ends of the ropes are attached to counterweights. They are used for mid and high-rise applications and have much higher travel speeds than hydraulic elevators. These make the elevators more efficient by offsetting some of the weight of the car and occupants so the motor doesn’t have to move as much weight. An electrically controlled brake between the motor and the reduction unit stops the elevator, holding the car at the desired floor level. The machine room is at the top of the hoistway and contains the machine and controller.

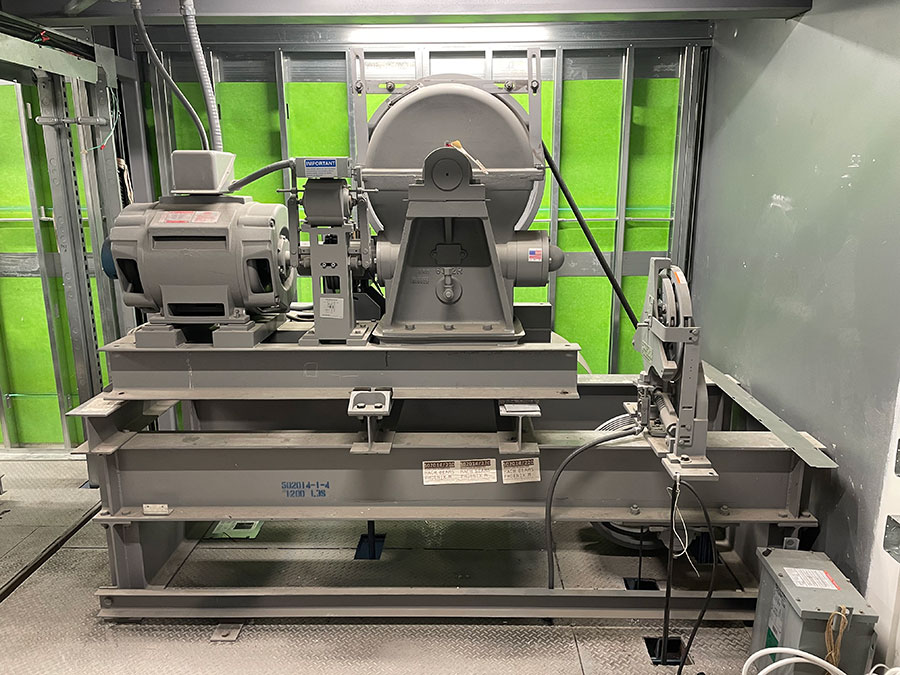

Geared Traction Elevators

These elevators are operated by a motor, which drives a worm-and-gear-type reduction unit, which spins the hoisting sheave. While the elevator rates are slower than in a typical gearless elevator, the gear reduction offers the advantage of requiring a less powerful motor to turn the sheave. These elevators typically operate at speeds from 125-500 feet per minute and can carry heavy loads.

Gearless Traction Elevators

These are some of the most used elevator types for tall buildings. The sheave is directly attached to the motor, and there is no reduction box or gears. Gearless traction elevators are capable of speeds up to 2,000 feet per minute. Also, they have a maximum travel distance of around 2,000 feet so they are the most common choice for high-rise applications.

Machine Roomless (MRL) Traction

Learn More

Overhead Traction

Learn More

Elevator Options

Which one is best for your project? The table below summarizes the capabilities of each.