Manufactured Elevators

PME elevators are built as one unit, fully ready for setup on the job site. We are able to deliver high-quality, commercial elevators in less time than the out-of-date, stick-built alternative.

We Use Industry Standard Parts

Our Process

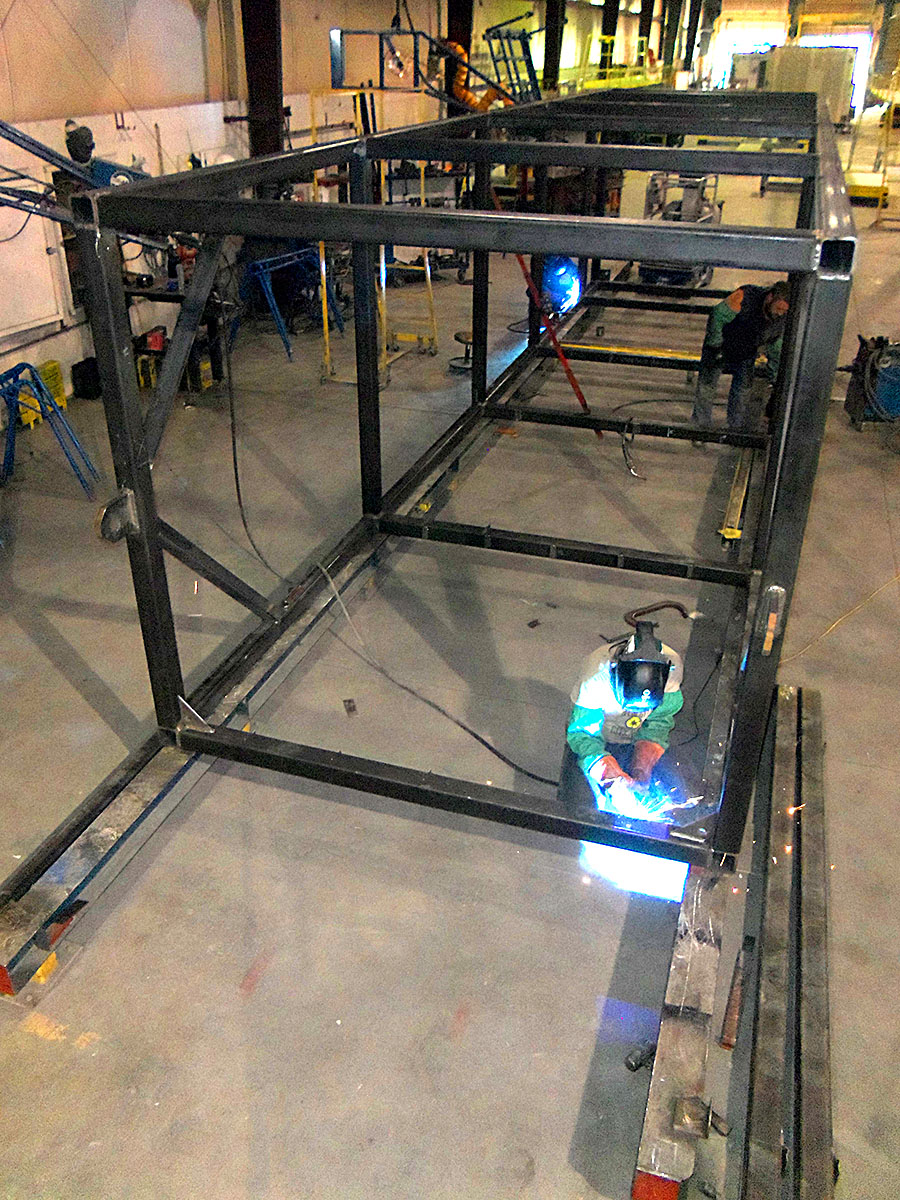

Step 1

Our manufactured elevators start with the hoistway frame built to customer specifications and building codes out of 4×4 inch tube steel columns and beams. This sturdy structure is self-supporting and can withstand earthquakes and 150 mph winds.

Step 2

Steel studs are then welded in place and entrance frames are installed. As needed per code, drywall is attached inside and out. This gives the manufactured elevator a one-hour or two-hour fire rating.

Step 3

Elevator equipment is then installed in the completed hoistway. Guide rails are precisely aligned, and hall stations and doors are installed and wired. Even the pit ladder, pit light and hoistway lights are included.

The entire hoistway is rotated, making the enclosure process safer and more efficient.

Step 4

At the same time, work begins on the elevator car. The sling and platform are fabricated on jigs to ensure precision, and the cab walls and ceiling are assembled and squared. All of the components, including guide shoes, door operators, light curtains, inspection station, interior lights and exhaust fan and doors, are put in place. This makes the car complete and ready for insertion into the hoistway.

Car assembly is safer and easier when it’s done outside the hoistway.

Elevators cabs should take hours to install, not weeks. See the process that is the fastest, safest and smartest way to install an elevator car.

Step 5

The final step, playfully called “stabbing the cab,” is inserting the completed cab into the still-horizontal hoistway. Because both are fabricated on jigs, the car’s guide shoes slide easily onto the guide rails, where the car and hatch doors are perfectly aligned. Traction cars are then roped while hydraulic elevators have their jacks installed. All of the systems are inspected for a final time and the car and doors are locked into place for shipping. The entire completed modular elevator is carefully lifted onto the back of a flatbed truck and shipped to its new home.

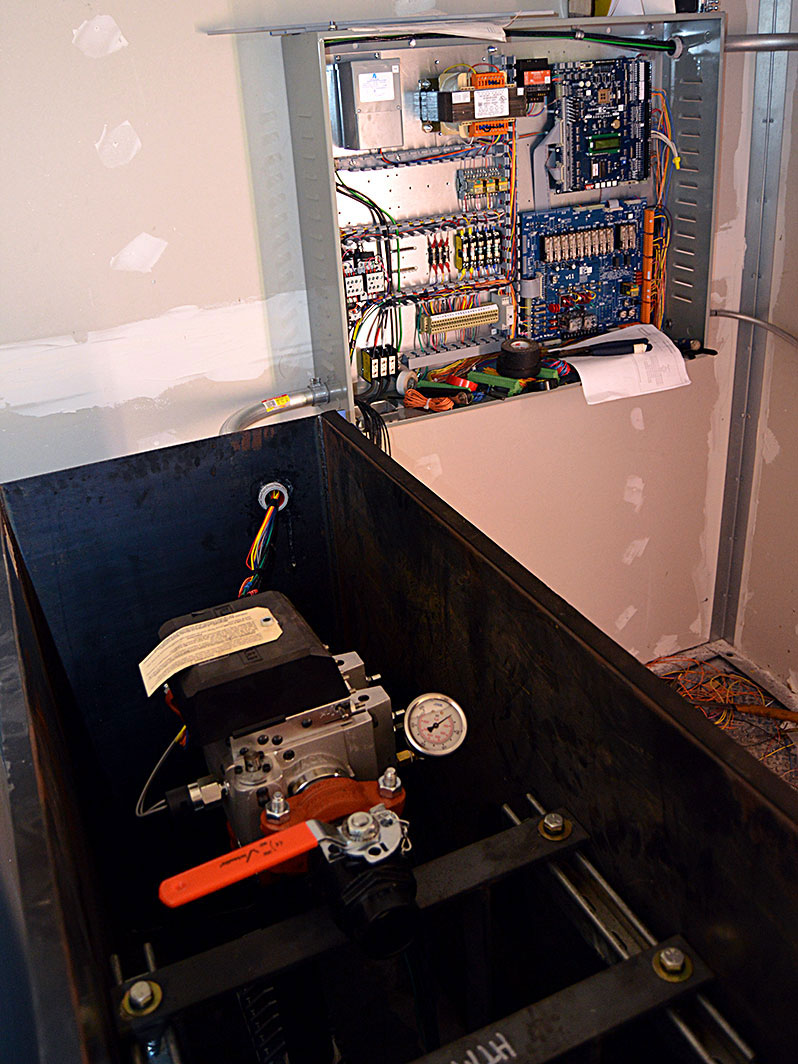

Step 6

If the project calls for a modular machine room, it is constructed with durable tube steel and galvanized studs. It is then covered in fire-rated drywall to meet code requirements. Overhead lighting, a GFCI outlet, and disconnects for the elevator power are installed, as well as the tank and controller. All equipment is pre-wired, trimming time off the install.

Step 7

Once the elevator arrives on-site, it is craned into place. The elevator mechanic then does the set up and performs final testing and adjusting. The elevator can be fully functional and ready for inspection in less than one week.